R&D Centre

The first 60 years for a hat production, the second 60 years for a pen nib production, and what's the next 60 years for?

Established a facility dedicated to our R&D, "NEXT", with the meaning of "next-generation technology" in 2018

Concept

1.To increase R&D speed

Everything from production to evaluation can be completed in the same R&D Centre, equipping with all the dedicated facilities.

While always monitoring the evaluation results without any delay, an acceleration of developments can be achieved.

2.Improvement of product development and enhancement of education

Everyone can acquire basic knowledge about the products and the latest information such as industry trends and the quality of competitors' products.

From beginners to professionals, we can work together on the product development.

Initiatives for the developments

We study trends from the global market research and customer's requests, and constantly develop products that meet their needs.

Here an example of our latest developments.

Developments of the new items

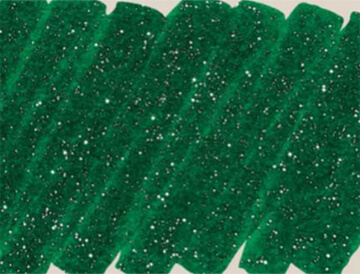

Case study: Ultrafine nib with hollow plastic feeder

Brush pen that has a sufficient ink flow and excellent glitter.

It is a new product from the big trends in the writing and cosmetic industry, using this kind of ink.

(Registration number JP,558718,B)

A technical standpoint

Newly developed an epoch-making structure of the nib, delivering the ink through both the fiber tip which is a making pen nib, and the hollow plastic feeder into which the fiber tip is put. The ink is being delivered by this double capillary force.

.png)

Enlargement

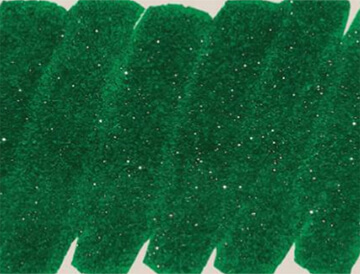

Regular (without hollow plastic ink feeder)

…Less shinny

New ( with hollow plastic ink feeder)

…Much shinny

Exploring new shapes of the nib

With our advanced grinding technology, the complicated shapes can be feasible.

Examples of unique shapes

Spatula shape

Kokeshi shape

Shark shape

Arrow shape

Screw shape

Hollow shape

The above shapes are only examples. It may be possible to grind the nibs in the shape customers request.